Farringdon Station Escalator Shaft 2

Engineer: Mott Macdonald

Contractor: BAM Ferrovial Kier Joint Venture

Market Sector: Complex Formwork for In-situ Concrete

Product: Formwork Solution

As part of the ongoing Crossrail project, Farringdon Station is undergoing a major development to increase capacity, improve accessibility and upgrade interchanges. It will also be one of ten new stations that will serve the Elizabeth Line when it opens in 2018. Cordek were tasked with providing a formwork solution to enable the main contractor to cast the ‘knuckle’ intersections between the escalator shaft and the levels above and below.

Project Scope

Unlike the straight part of the tunnel which could be formed using traditional formwork, the complex geometry of the top and bottom intersections required a unique formwork solution to form the secondary tunnel lining. The design had to accommodate the restricted access to the project and recognise that the formers needed to be suitable for manual handling.

The Solution

Cordek worked closely with the main contractor BAM Ferrovial Kier Joint Venture to develop a formwork concept which could be installed in stages to suit the preferred concrete pour sequence required for this complex structure. From the Engineer’s 2D drawings Cordek were able to generate a 3D model of the surface of the tunnel lining. Using this model, the surface was then subdivided into manageable individual formwork units which were lightweight enough to handle but also able to withstand the concrete pressure during casting. Designed into the model were a network of tie bolts which could be used to accurately locate and secure the units into position. The units were designed using a Filcor 70 flame retardant EPS (expanded polystyrene) core with a fibreglass coating on the forming face to ensure easy striking. A plywood backing was also included for strength and support.

The Process

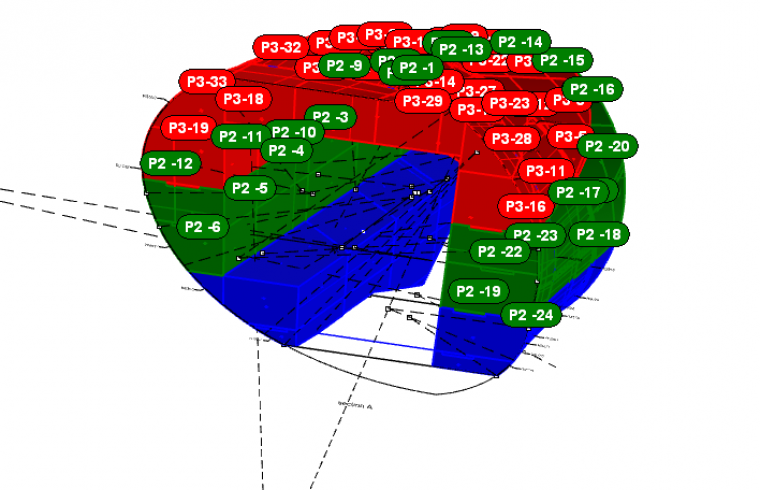

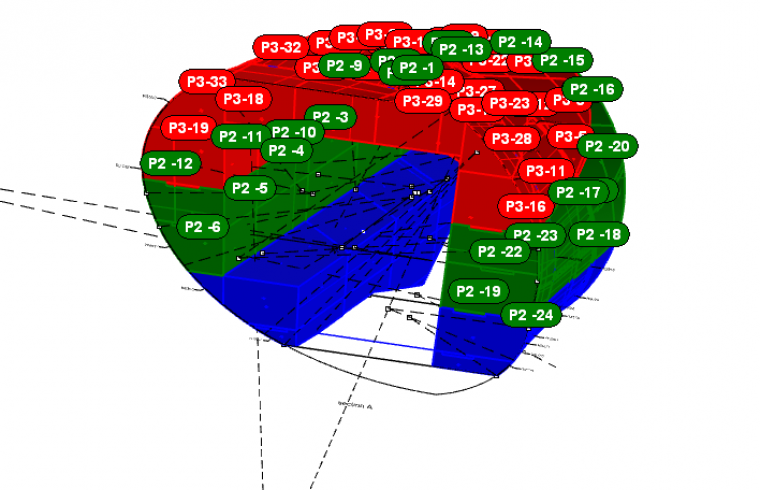

The units were manufactured to tight tolerances at Cordek’s digital engineering facility. Firstly the complex forming surface was machined and the tie bolt holes formed, then threaded anchor plates were embedded into the Filcor EPS. The holes for the anchor plates were then filled and faired before the fibreglass coating was applied and finally the plywood backing bonded into position. The formers were manufactured and delivered in three stages over an eight week period to suit the contractors programme. The first stage of the installation was to position the blue and green units as shown in Figure 1 below. This allowed the lower section of the tunnel lining to cast before a temporary deck was installed to support the units shown in red. With these in position the contractor was then able to cast the crown of the tunnel lining.

Summary

The success of this formwork solution was a combination of the initial detailed collaboration between Cordek and BAM Ferrovial Kier Joint Venture coupled with Cordek’s expertise in designing and manufacturing complex formwork. Working within the restrictions of the tunnels access points and the resources available to fix and strike the units, the design kept the overall number of units to a minimum. The station is due to open in December 2018 when services begin through central London.

Download Case Study PDF

Download Case Study PDF