Ely Southern Bypass

Main Contractor: VolkerFitzpatrick

Sub-Contractor: Sword Construction UK Ltd

Architect: Knight Architects

Market Sector: Bespoke Formwork Solutions

Product: Bespoke Formwork

The Ely southern bypass is a new road connecting the A142 at Angel Drove to the Stuntney Causeway. It is hoped that the bypass will help to ease congestion in and around Ely by providing a new link to the south of the city. The 1.7km long single carriage way road includes a 300m long viaduct crossing the Great Ouse River, for which Cordek were called upon to supply a bespoke formwork solution for the construction of the complex geometrical details of the supporting piers.

Project Scope

The design of the 300m long viaduct deck included three bidirectionally, tapered supporting piers. Skewed in plan, these three 16 metres long, ‘V-shape’ piers, varied in height across the water and supported the viaduct deck whilst also providing an aesthetical feature to the reinforced concrete structure.

The specialist civil engineering sub-contractor, Sword Construction UK Ltd, approached the Cordek Project Design Team to assist them in designing a formwork solution to form the radius chamfers spanning four metres in length, along with shadow gaps used to break up the edge of the concrete and add an interesting visual element to the twin trapezoidal box girders.

The Solution

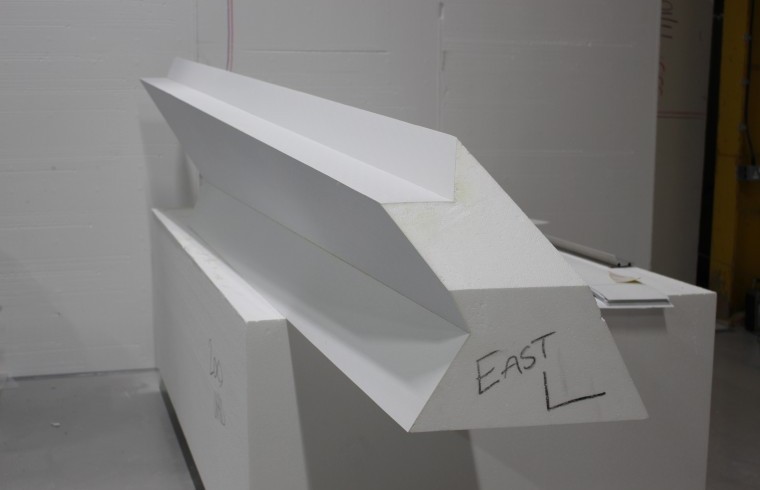

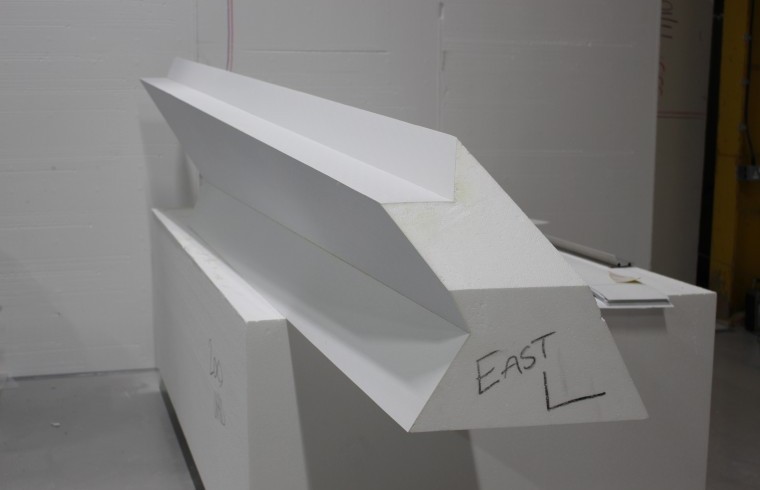

The lead designers for the project had decided upon reinforced concrete to construct the piers, due to its flexibility in form and shape, combined with the ability to achieve a F3/F4 finish. The double curving, complex geometry of the chamfers and shadow gaps meant that it would have been difficult to utilise a traditional formwork material or system and therefore a bespoke solution was required. A pair of formers was proposed to construct each of the piers and where possible the formwork was manufactured from profiled Filcor 70 Expanded Polystyrene (EPS) with an ABS skin, to produce the required surface finish. Due to the overall length of the double curving aspect of the radius chamfers necessary to create the ‘V-shape’ design feature, in certain locations there was the additional requirement for a flexible rubber profile to be used in conjunction with the main formwork system.

Each former comprised a total of eight individual units, enabling manual handling on site. Consideration also had to be made to where the joint lines were positioned within the formwork solution and how they would impact on the concrete finish achieved.

The Process

Following receipt of 2D CAD information, the Cordek Project Design Team created a 3D model of the ‘V-shaped’ piers which was used to design the formwork solution. Use of digital modelling also aided the contractor to view and understand the proposal including the assembly, positioning, pouring and striking sequences.

The Filcor 70 EPS formwork solution was profiled using a 5-axis CNC router, producing a representation of the CAD design to within a millimetre. Due to the size of some of the units (2-3m in length), blocks of Filcor 70 EPS were bonded together, before being routed to the required profile and the ABS skin applied to the surface. For the manufacture of the rubber profiles, triangular shaped moulds were created out of model board prior to pouring the castable rubber compound. Once they had cured, the flexible pyramid shaped profiles were demoulded and positioned on the routed Filcor 70 EPS units to form the edge detail of the ‘V’ shape piers.

On site the formwork solution was positioned and tied in to the steel reinforcement prior to placement of concrete. The concrete was poured in two stages due to the height and weight of the overall structure. The first pour was carried out before being allowed to cure, following which the formwork was struck. Additional reinforcement was tied into the exposed rebar from the first pour, with the repositioning of the formwork prior to the final concrete pour being carried out.

Summary

Cordek helped to design and deliver a bespoke formwork solution which aided the construction of the ‘V-shape’ piers which provide a unique aesthetic feature to the project. The bypass was officially opened on the 31st October 2018, much to the delight of the local residents and commuters, for which it has been a long awaited improvement to the surrounding highway network.

Download Case Study PDF

Download Case Study PDF