PROJECT FOCUS

Battersea Power Station Staircase

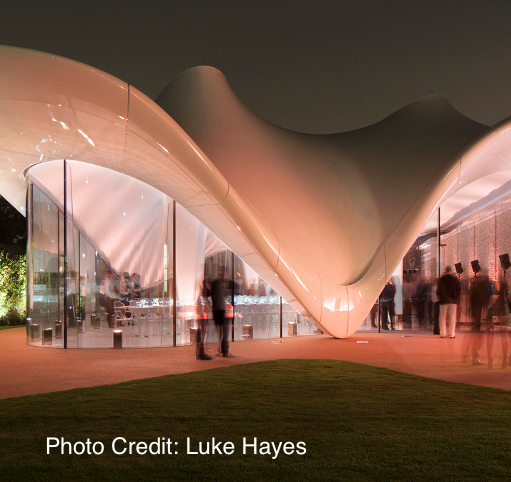

Circus West Village at Battersea, designed by Architects SimpsonHaugh & Partners, was the first completed phase of the Battersea Power Station development plan and set the standard in terms of quality of design and execution for all following phases.

Project Requirements:

Moulds to produce 100 pre-cast concrete spiral staircase castings without loss of quality. Geometric accuracy was important to ensure all steps aligned with cast in-situ landing levels.

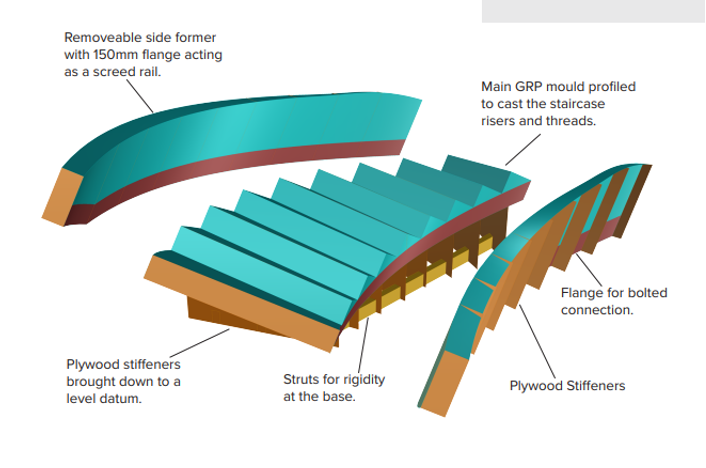

Mould Design:

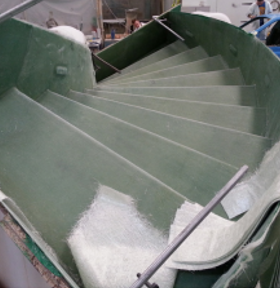

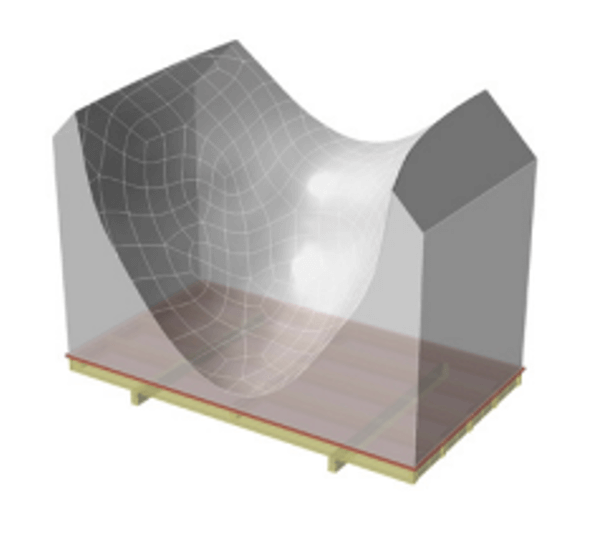

The Architectural design was rationalized to produce all 100 flights using just 4 GRP moulds. The design allowed for the stair sections to be cast upside down (treads facing downwards) to achieve the best quality on the top surface and the concrete soffits screeded flat against rails incorporated into the GRP mould design to ensure accuracy. Mould edges were designed to be unbolted from the main form to facilitate easy striking on the pre-cast units.

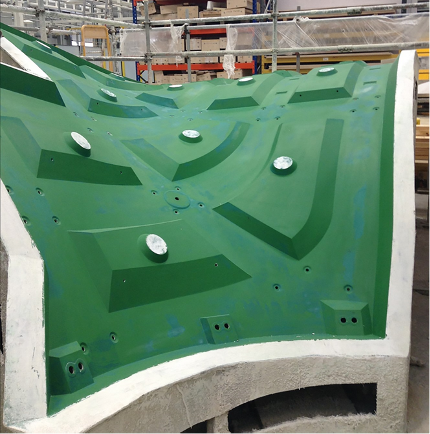

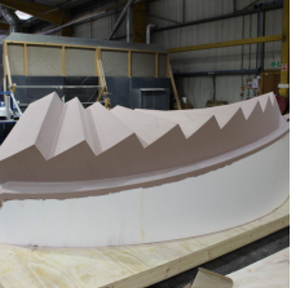

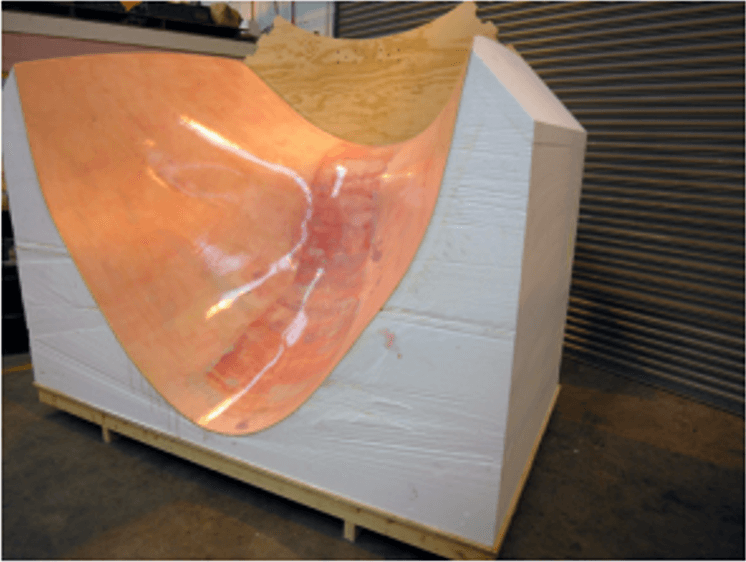

Mould Production:

An accurately machined pattern was produced on a 5-axis router from EPS coated in epoxy tooling paste. The pattern included machined screed rails on both sides to precisely set the line of the curved stair soffit. A direct GRP mould was taken from the pattern and reinforced with plywood stiffeners. These were fitted closely behind the casting faces and were cut to a level datum so that once the mould was placed casting face up, they would act as a flat support table. Removable edges allowed for fast and efficient extraction of the cured concrete units.

Cordek Supplied

4 no unique GRP moulds that successfully pre-cast 100no flights of stairs to the required dimensional accuracy and quality.

.png?v=1717423734198)

.png?v=1717421923988)

_(1).jpg?v=1717412133110)