Corbreak is a unique system to aid the trimming down of piles. During the construction of piled foundations, it is generally necessary to reduce the height of the piles and expose the reinforcement within them. The removal of concrete required to do this has been traditionally carried out using hand held tools which subject the users to a number of health and safety related issues e.g. noise and vibration.

Features

- Manufactured from a lightweight Filcor

- No chemicals required during the installation or removal process

- Reduces the breaking out time when compared to traditional methods

- Removal can be carried out quietly, without the need for hand held tools

- Avoids the risk of cracking the pile when using heavy hydraulic breakers

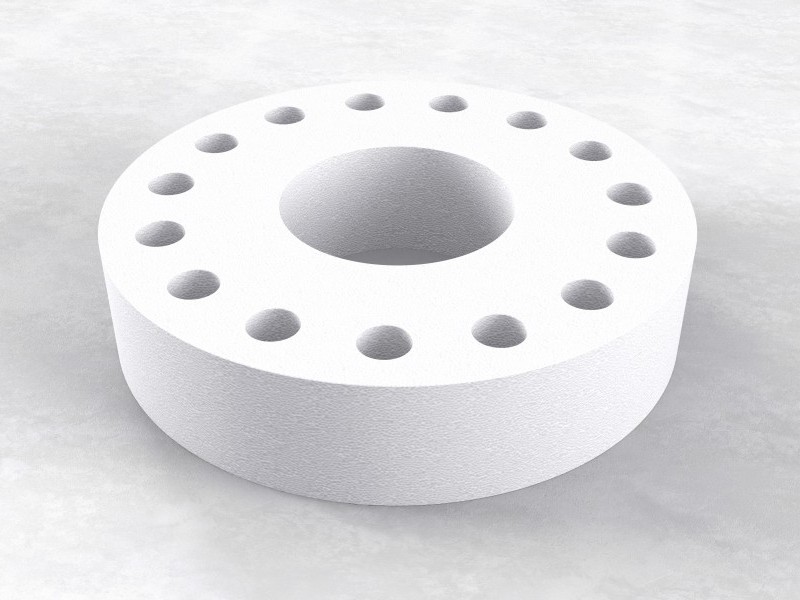

Corbreak units are a fast, quiet and economic solution to the problems associated with the trimming down of piles. Manufactured from Filcor (Expanded Polystyrene), the product is fixed into the pile reinforcement cage prior to placing the cage into the borehole. After casting of the pile and exposure of the top of the pile shaft, the Corbreak unit allows the top of the pile to be cracked and lifted off thereby reducing the height of the pile to the required level.

Applications

For aiding the trimming down of concrete piles to the required height / level and to allow the exposure of reinforcement.

Suitability

Each Corbreak unit is manufactured to the specific project requirements based upon the pile diameter, positioning of reinforcement bars and required thickness.

Environmental facts about Filcor EPS

The manufacture of Filcor is a low pollution process. Steam is he key component and the water is re-used many times. There is no waste in the process as all cut offs or rejects are recycled.

Filcor is 98% air. This makes Filcor a uniquely resource-efficient material with small carbon footprint.

Filcor is HFC, CFC and HCFC free and Pentane is used as its blowing agent. Pentane has a low Global Warming Potential* (GWP) of less than five. (The EU does not register pentane as a substance hazardous to human health or environment.)

Styrene, used in the manufacture of Filcor, occurs naturally in many commonplace items including strawberries, beans, nuts, beer, wine, coffee beans and cinnamon

Filcor is 100% recyclable. As a single polymer, Filcor is straightforward to recycle and is recyled into items such as replacement hardwood decking or garden furniture and coat hangers

.jpg?v=1669292955)

.jpg?v=1669292965)

.jpg?v=1669292996)

User Notice

To view our technical documents, we recommend using alternative internet browsers to Chrome (such as Microsoft Edge, Internet Explorer, or Firefox) whilst Google rectify their Chrome browser and PDF document compatibility issue. We apologise for any inconvenience caused.