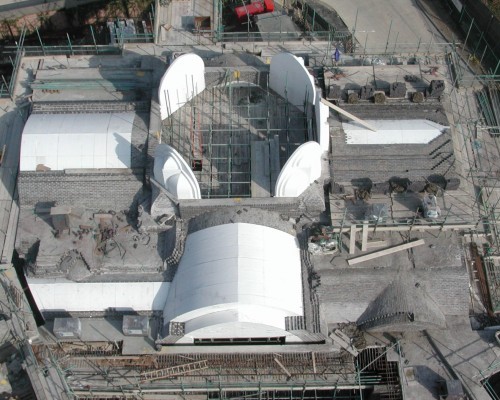

Arch Formers

When constructing in-situ cast reinforced concrete or masonry arches, it is common practice to employ the use of temporary falsework until the structure is self-supporting.

Arch formers manufactured from lightweight Filcor (Expanded Polystyrene) are an economical method of providing temporary support to arched / curved masonry structures whilst in construction. In order to minimise costs, arch formers can be used in conjunction with traditional falsework e.g. scaffolding to support them at the required height.

Each former is designed to meet the specific requirements of the project including the size, shape, finish and number of re-uses. Using this information, our designers will select the most appropriate material for each former and create a 3D CAD model for approval, which when accepted will allow CNC machining of the finished formwork solution.

Features

- Manufactured to meet project specific requirements

- Robust construction usually* comprising Filcor EPS with a Correx skin (outer surface)

- Lightweight, quick and easy to install / remove / store

- CNC machined for consistent, tolerance-controlled surfaces

- Re-usable where arches of the same size, shape and profile are required

*Alternative materials are available upon request and can be supplied to achieve concrete finishes as outlined in the National Structural Concrete Specification (NSCS) Edition 4 guidance available below.

Applications

Used to provide temporary support to reinforced concrete or masonry arch structures during construction.

Design

When developing an arch former design, the following factors should be considered in addition to reviewing any CAD drawings, 3D models, specifications etc that are available:

- Dimensions, geometry and features

- Required concrete finish (Basic, Ordinary, Plain or Special)

- Proposed number of uses – single or multiple

- Loadings – specifically relating to the proposed concrete pour depths

- External structural support method

- Delivery method, unloading requirements and access restrictions

- Positioning, installation and sequence of construction

- Striking, removal and re-use or disposal

Once the project requirements have been confirmed, a conceptual design can be completed along with provision of a quotation confirming proposed material type, features, quantities, manufacturing lead time and costs.

Materials & Finishes

Materials & Finishes:

Typically, Cordek arch formers are manufactured from one of the following material types:

- Filcor Expanded Polystyrene (EPS)

- Filcor EPS with Correx skin

- Filcor EPS with ABS skin

- Filcor EPS with Sheet Fibreglass skin

- Filcor EPS with a spray applied Polyurea skin

- Glass Reinforced Plastic (GRP)

One of the factors determining the most appropriate material used to manufacture an arch former is the required concrete finish. Further information in relation to the classification of concrete finishes can be found within the National Structural Concrete Specification (NSCS) Edition 4 guidance, a copy of which can be downloaded from the Certification, Guidance and Approval section below.

Manufacture

Once approved, the agreed 3D CAD Model will be converted in to CAM data allowing accurate manufacture of the arch former via CNC hot wire cutting and / or 5-axis routing dependant on factors such as material type, complexity of shape / profile and required tolerances.

In some instances, due to the required dimensions of the arch former, it may comprise of a number of individual units that require assembly on site

Environmental facts about Filcor EPS

The manufacture of Filcor is a low pollution process. Steam is he key component and the water is re-used many times. There is no waste in the process as all cut offs or rejects are recycled.

Filcor is 98% air. This makes Filcor a uniquely resource-efficient material with small carbon footprint.

Filcor is HFC, CFC and HCFC free and Pentane is used as its blowing agent. Pentane has a low Global Warming Potential* (GWP) of less than five. (The EU does not register pentane as a substance hazardous to human health or environment.)

Styrene, used in the manufacture of Filcor, occurs naturally in many commonplace items including strawberries, beans, nuts, beer, wine, coffee beans and cinnamon

Filcor is 100% recyclable. As a single polymer, Filcor is straightforward to recycle and is recyled into items such as replacement hardwood decking or garden furniture and coat hangers

.jpg?v=1669292955)

.jpg?v=1669292965)

.jpg?v=1669292996)

User Notice

To view our technical documents, we recommend using alternative internet browsers to Chrome (such as Microsoft Edge, Internet Explorer, or Firefox) whilst Google rectify their Chrome browser and PDF document compatibility issue. We apologise for any inconvenience caused.